Notching is a process for cutting metal that’s mainly used on thin bar stock, metal sheets, and sometimes even on tubes or angle sections.

But, you need to know the proper uses of tube notchers for implementing them in metalwork. That’s why we’ve explored the answers to the question, tube notcher: what is it used for?

Punching is a possible way of cutting the tubes, but it requires a lot of work and some complex handling of the tube. Metal tubes are hollow objects. So, it’s not quite practical to notch it with a simple punch operation.

If you do it, the chances of squashing the tube are much higher. This is why tube notching is far more practical and commonly used for circular tubes.

What Is a Tube Notcher?

Before we get into what a tube notcher actually is, let’s get to know a bit more about tube notching itself.

As mentioned above, tube notching is a more practical way of notching a tube without punching the tube and potentially damaging or just squashing the tube.

Now, a tube notcher is basically a tool for creating notches of fishmouth in pipes. When it comes to tube notching, there are three types of notching that are mainly done.

Tube Notching

It’s normally done to make a tee joint or just any similar joints before joining light gauge tubes with the help of welding. Before the assembly, either one or even both tubes might be notched.

A common example of tube notching would be bicycle frames. They’re manufactured with tube notching.

Side Notching

Side notching is also often called offset notching. Just as the name implies, side notching is working with the side of a tube in order to bend it with a Vee notch. For tee joints, it generally uses Vee notches or semicircular joints.

End Notching

This type of notching works with the ending of a tube. It can be used to make the base for a tee joint with a semicircular concavity. Using end notching to make a concave Vee in order to fit in a miter is also a common technique.

What Is a Tube Notcher Used for?

Now that we understand tube notching itself let’s look at what tube notchers are and what they’re mainly used for.

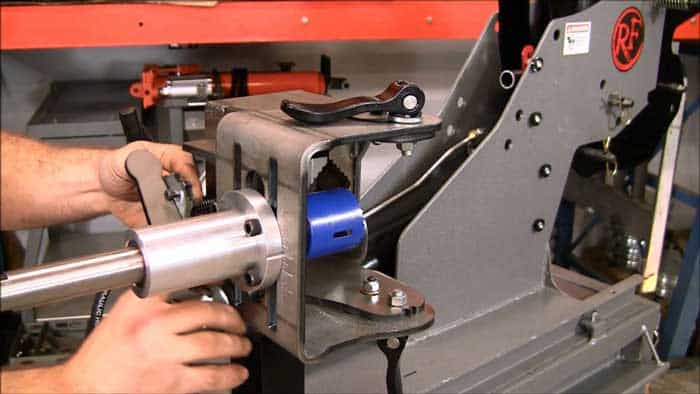

So, a tube notcher is mainly used when you need to cope pipes or round tubes. It can be for building gates, furniture, roll cages, or even handrails. Coping is basically when you join a piece of tubing to another.

Manual notching or coping requires extensive precision. You’ve got to find out the angle for cutting the tube that you’ll be joining to the side of the other tube.

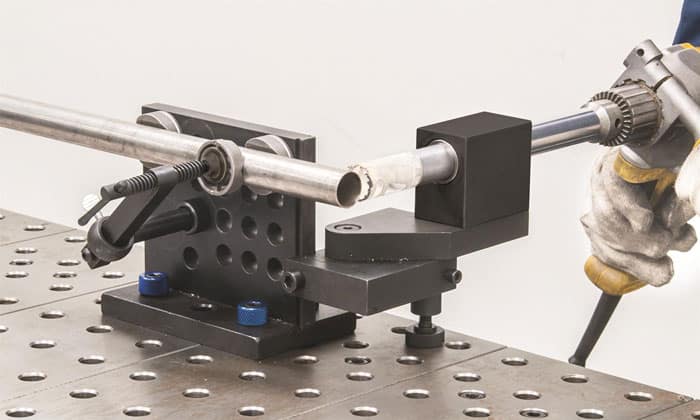

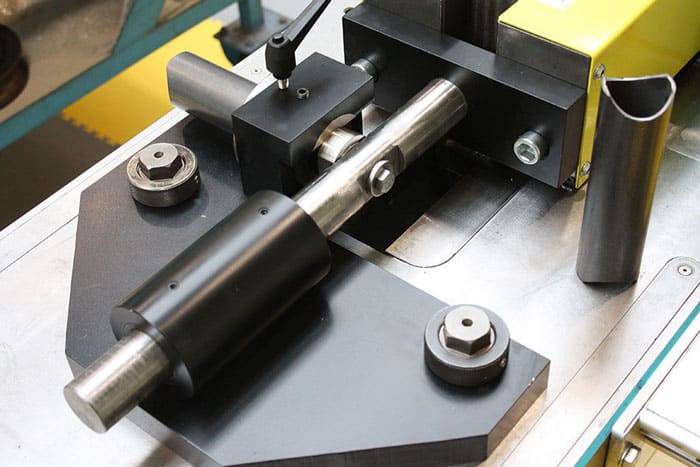

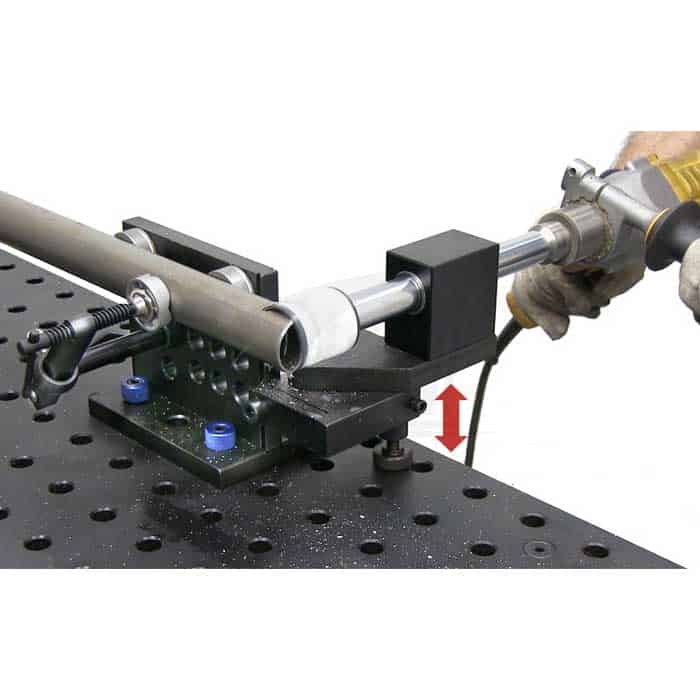

This can take a long time to go through the manual process with lots of trial and error and angle finders. A tube notcher uses a hole saw mounted on a shift. It also has a clamp that is adjustable for holding the tube in place. This is why using a tube notcher is a lifesaver.

Benefits of a Tube Notcher

With a tube notcher, you’ll be saving lots of valuable time and material along with other benefits.

- You won’t have to deal with manually spending hours to get the right angle. Most of the tube notchers already come with an angle finder installed on them, so you can get all those angles right.

- Using a tube notcher also gives a lot more precise results at the end than you would get going in with a notch manually.

- Tube notcher can make your project far more accurate and a lot more durable in the long run.

However, most of the tube notchers only go as low as 55 degrees. If you want anything lower than that and your tube notcher doesn’t allow the setting, then you’ll have to use a grinder to modify the cope.

Frequently Asked Questions

1. What are the safety concerns with a tube notcher?

Tube notchers, just as most tools used in metalworking, require some safety when working. Since they have sharp teeth that cut through metal, you should wear protective glasses for your eyes and use heavy gloves to protect your hands from any cuts.

2. Is a tube notcher worth it?

If you want your projects to be more precise and have more rigidity, it’s definitely worth the investment. It’s a great tool to use for metalworking and makes your life a lot easier.

3. Can you make a fishmouth with a tube notcher?

Yes, with a tube notcher, you can make “fishmouth” notches in pipes or metal tubes to connect them to another tubing.

Final Words

So, if you’ve been wondering, tube notcher: what is it used for, this article should’ve answered your queries. A tube notcher can make your garage work a lot simpler and quicker.

You don’t need to deal with the hassle of measuring everything to the point and wasting material; you can just get the perfect results using a tube notcher in no time!